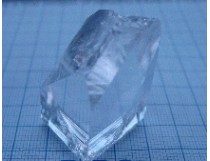

BiBO Crystals

BiBO crystal features a large effective nonlinear coefficient (3.5 - 4 times higher than that of LBO, 1.5 - 2 times higher than that of BBO, ~ 8 times higher than that of KDP), high damage threshold and inertness to moisture. In particular it has been identified over the past years to be an efficient crystal for producing green or blue light through second harmonic generation (SHG) of Nd lasers or ultrafast TiS lasers. It also has an important application in efficient generation of ultrabright entangled photons through blue pumped spontaneous parametric down conversions (SPDC).

BiBO products on this page are thick crystals (T > 3 mm) for applications with picosecond (ps), nanosecond (ns), or long pulse/CW lasers.

For thin BiBO products (T =< 3 mm) developed for frequency conversions of ultrafast femtosecond (fs) lasers, please visit thin BiBO crystals.

For BiBO products (including paired BiBO crystals) developed for spontaneous down conversions (SPDC), please visit SPDC components.

| Part No. | Description | Application | Thickness | Price | Availability | Add to Cart |

Newlight's BiBO features:

Structural and Physical Properties:

| Crystal Structure | Monoclinic, Point group 2 |

| Lattice Parameters | a=7.116 Å, b=4.993 Å, c=6.508 Å, β=105.6°, Z =2 |

| Melting Point | 726°C |

| Mohs Hardness | 5 - 5.5 |

| Specific Heat | 0.5 J/gm-K at 330 K |

| Thermal Expansion | 4.8x10-5[X], 4.4x10-6[Y], -2.69x10-5[Z] |

| Density | 5.033 g/cm3 |

Optical Properties:

| Transmission Range |

286-2500 nm |

| NLO Coefficients | d11=2.53 pm/V, d12=2.93 pm/V, d13=-1.93 pm/V, d14=1.63 pm/V d25=1.67 pm/V, d26=3.48 pm/V d35=-1.58 pm/V, d36=1.67 pm/V (defined in the principal optical axes xyz: nz>ny>nx, x-1, y-2, z-3) |

| Refractive Indices | @539.75 nm: nx = 1.7874, ny = 1.8190, nz = 1.9620 @1079.5 nm: nx = 1.7569, ny = 1.7835, nz = 1.9166 |

| Sellmeier Equations (λ in µm) |

nx2=3.0740+0.0323/(λ2-0.0316)-0.01337λ2 ny2=3.1685+0.0373/(λ2-0.0346)-0.01750λ2 nz2=3.6545+0.0511/(λ2-0.0371)-0.0226λ2 |

Application examples:

@473 nm was obtained from frequency doubling of 4.6 W CW Nd:YAG @ 946 nm with BiBO |

Comparison of Nonlinear Optical Properties of Crystals for SHG @ 946 nm:

| Crystals | Length (mm) |

Deff (pm/V) |

Walk-off (mrad) |

Output Power(W) |

Conversion Efficiency |

| BiBO | 10.4 | 3.3 | 40.7 | 2.8 | 63% |

| LBO | 10 | 0.81 | 11.3 | 1.52 | 33% |

| BBO | 8 | 2.0 | 60.3 | 2.1 | 47% |

Specifications of BiBO components:

| Wavefront Distortion: | < λ/6 @ 633 nm for for Aperture =< 5mm, L =< 5mm |

| Dimension Tolerance: | (W+/-0.1 mm) x (H+/-0.1 mm) x (L+0.2/-0.1 mm) |

| Clear Aperture: | > 90% central area |

| Flatness: | Better than λ/6 @ 633 nm |

| Surface Quality: | Scratch/Dig 20/10 per MIL-O-13830A |

| Parallelism: | Better than 30 arc seconds |

| Perpendicularity: | 5 arc minutes |

| Angle Tolerance: | Δθ < 0.25o, Δφ < 0.25o |

Coatings:

Single-band, dual-band or broad-band AR coatings on BiBO crystals are available upon request.

Coating curves (Typical):

AR800/400 nm, AR1064/532 nm, AR1550/775 nm, AR1850/925 nm, BBAR centered ~ 700 nm

Angular tuning:

OD 1" crystals can be mounted in a conventional 1" mirror mount to be angle tuned for phase matching ( as shown to the right).

BiBO Crystal Handling:

The susceptibility to moisture of BiBO is very low. However, users are advised to provide dry conditions for both use and storage of BiBO to prolong the lifetime. Water condensation on crystal surfaces should be absolutely avoided at any time.

Cleaning Crystals:

Dust and stains on crystal surfaces can cause scattering/loss of light and can even react with light to damage optical surfaces at a high incident laser power.

Inspect the crystal surface for dust and stains by holding it near a bright visible-light source. Viewing at different angles can help see scattering from dust and stains. The crystal surface has to be cleaned as described below if dust and stains are found.

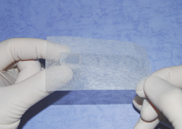

Note: Perform the following cleaning procedures in a clean, low-dust environment while wearing powder-free gloves or finger cots.

1. Blowing off the crystal surface

Use a canister of compressed N2/clean air or a blower bulb (e.g., http://www.adorama.com/GTRABS.html ) to blow off dust and other loose contaminants first. If a dry nitrogen line is available in the lab, an air gun can also be used to blow away dust particles. Blow off the surface gently. Do not blow off the crystal itself from your hand!

2. Drop and Drag Method

Hold the crystal so that the c rystal surface is horizontal and slightly above your fingers. Take a fresh, clean sheet of lens tissue and place it on the crystal. Make sure the lens tissue can be drawn across the crystal surface. Next, place a small drop of pure isopropyl alcohol (IPA) on the lens tissue on top of the crystal surface. The weight of the solvent will cause the lens tissue to come into contact with the crystal surface. Slowly but steadily drag the damp lens tissue across the crystal surface being careful not to lift the lens tissue off of the surface. Continue dragging the lens tissue until it is off of the surface.

rystal surface is horizontal and slightly above your fingers. Take a fresh, clean sheet of lens tissue and place it on the crystal. Make sure the lens tissue can be drawn across the crystal surface. Next, place a small drop of pure isopropyl alcohol (IPA) on the lens tissue on top of the crystal surface. The weight of the solvent will cause the lens tissue to come into contact with the crystal surface. Slowly but steadily drag the damp lens tissue across the crystal surface being careful not to lift the lens tissue off of the surface. Continue dragging the lens tissue until it is off of the surface.

The amount of the solvent can be adjusted for various crystal size so the lens tissue is kept damp for the entire drag but there is not any visible trace of solvent on the crystal surface after the drag is finished. Inspect the surface and repeat if necessary, but only use each sheet of lens tissue once.

If the crystal surfaces are still “dirty” after the above cleaning procedures, the surfaces might have been damaged. Please contact us for rework of the crystals.

If you do not find the suitable products above, you may let us know your requirements or applications in the form below. Our sales or technical staff will get back to you as soon as possible.

Please provide your contact information for us to get back to you:

Name:Title:

Organization:

Work Phone:

E-Mail Address:

Enter the code in the box below: