alpha-BBO Crystals

High temperature phase BBO (alpha-BBO, a-BBO) is a negative uniaxial crystal with a large birefringence over the broad transparent range from 189 nm to 3500 nm. The physical, chemical, thermal, and optical properties of alpha-BBO crystal are similar to those of the low temperature phase beta-BBO crystal. However, there is no second order nonlinear effect in alpha-BBO crystal due to the centrosymmetry in its crystal structure and thus it has no use for second order nonlinear optical processes. Instead, alpha-BBO is widely used for fabrication of polarizers, polarizing beam displacers, phase retarders, birefringent plates, and time delay compensators especially those for UV and high power lasers.

On this page are birefringent alpha-BBO plates or blocks. For polarizing optics manufactured from alpha-BBO crystal, please visit Polarizing Optics.

alpha-BBO crystal wedges/prisms are also available. Please check the "Tech Info" tab below.

| Part No. | Description | Thickness | Orientation | Price | Availability | Add to Cart |

Basic Properties of alpha-BBO Crystal:

| Transparency Range: 189 - 3500 nm |

|

|||

| Crystal Symmetry: Hexagonal, Space group R3c | ||||

|

Lattice Constants: a=b=7.2351A, c=39.192A |

||||

| Density: 3.85 g/cm3 | ||||

| Thermo-Optic Coefficients (for reference) dno/dT ~ - 9.3 x 10-6 /oC dne/dT ~ - 1 6 .6 x 10-6/oC |

||||

| Damage Threshold (10 ns, 10 Hz) 1 GW/cm2 @ 1064 nm, 500 MW/cm2 @ 532 nm |

||||

| Optical Homogeneity: Δn < 10-6/cm | ||||

| Mohs Hardness: 4.5 | ||||

| Thermal Expansion Coefficients (in the range of 25–900oC) |

αa = 4 x 10-6/K αc = 36 x 10-6/K |

|||

| Linear Absorption Coefficients: α<0.005 cm-1 from 300 to 2300 nm | ||||

|

Sellmeier Equations (λ in µm) : |

||||

| Wavelength (nm) | no | ne | Birefringence (Δn=ne -no) |

Walk-off Angle at 45° |

| 1550 | 1.6346 | 1.5190 | -0.116 | 4.19° |

| 1064 | 1.6396 | 1.5225 | -0.117 | 4.23° |

| 800 | 1.6448 | 1.5259 | -0.119 | 4.28° |

| 775 | 1.6456 | 1.5264 | -0.120 | 4.29° |

| 632.8 | 1.6513 | 1.5301 | -0.121 | 4.35° |

| 532 | 1.6582 | 1.5347 | -0.124 | 4.42° |

| 400 | 1.6763 | 1.5471 | -0.129 | 4.58° |

| 355 | 1.6876 | 1.5554 | -0.132 | 4.66° |

| 266 | 1.7301 | 1.5900 | -0.140 | 4.81° |

Specifications of alpha-BBO components:

| Wavefront distortion: | less than λ/8 @ 633 nm |

| Clear aperture: | > 90% central area |

| Flatness: | λ/4 @ 633 nm |

| Surface quality: | 20/10 Scratch/Dig per MIL-O-13830A |

| Parallelism: | better than 30 arc seconds |

| Perpendicularity: | 10 arc minutes |

| Angle tolerance: | Δθ < 0.25o, Δφ < 0.25o |

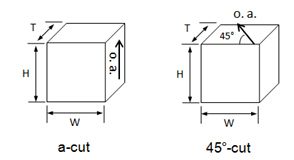

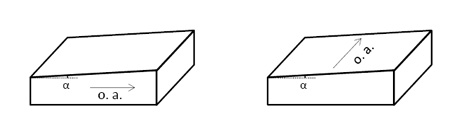

Common cut orientations of a-BBO crystals:

Prisms:

a-BBO crystals with a wedge angle (α) can be custom fabricated with the specified orientation of the optical axis. A paired or such prisms with the optical axes orthogonal to each other can be used to continuously adjust the phase shift or time delay between two orthogonally polarized pulses.

Coatings:

Standard a-BBO crystal products are coated with a single layer MgF2 protective coating (P-coating). Unprotected polished surfaces can degrade by ambient moisture due to the hygroscopicity of the material.

Anti-reflection coatings (AR coating) are available upon request. AR coating is a multiple layer dielectric coating with R<0.25% at the specified wavelength(s). AR coating also protects the surfaces from ambient moisture.

Typical P-coating curve: P-coating

Typical AR coating curve: AR800/400nm

Please specify the coating and append to the part number, e.g.

ALB5010-A-P for the a-cut a-BBO crystal with P-coating, and

ALB5010-A-AR800/400 for the a-cut a-BBO crystal with the dual AR coating @ 800/400 nm.

Substrate:

Ultrathin crystals of thickness 50 µm (0.05 mm) or thinner are supplied optically contacted on UV fused silica substrates with a typical thickness of 2.0 mm.

Mount:

For customer convenience and protection of crystals, crystals can be pre-mounted in a 1" ( 25.4 mm ) anodized aluminum holder. A standard 1" mirror mount may be conveniently used to tune the crystals for optimized birefringence or time delay. A rotation stage may be further used if a larger angular change is needed.

OD 0.5" (12.7 mm) holders for smaller crystals or OD 30 mm holders for larger crystals are available upon request.

If you do not find the suitable products above, you may let us know your requirements or applications in the form below. Our sales or technical staff will get back to you as soon as possible.

Please provide your contact information for us to get back to you:

Name:Title:

Organization:

Work Phone:

E-Mail Address:

Enter the code in the box below: