BBO Crystals

BBO crystal remains the most versatile nonlinear optical crystals thanks to its unique combination of optical properties (e.g. broad transmission and phase matching ranges, high damage threshold) and availability of large, high quality single crystals. Newlight's BBO crystals have been widely used in second, third, fourth or fifth harmonic generations for high power visible/UV sources, and optical parametric conversions for high power broadly tunable sources.

BBO products on this page are thick crystals (> 3 mm) for applications with picosecond (ps), nanosecond (ns), or long pulse/CW lasers.

For thin/ultrathin BBO products (thickness: 0.01 mm - 3 mm) developed for frequency conversions of ultrafast femtosecond (fs) lasers, please visit thin/ultrathin BBO crystals.

For BBO products (including paired BBO crystals) developed for spontaneous down conversions (SPDC), please visit SPDC components.

| Part No. | Description | Application | Size | Price | Availability | Add to Cart |

Newlight BBO features,

Structural and Physical Properties:

| Crystal Structure | Trigonal, Space group R3c, Point group 3m |

| Cell Parameters | a = b = 12.532 Å, c = 12.717Å, Z = 6 |

| Melting Point | 1095°C |

| Transition Temperature | 925°C |

| Mohs Hardness | 4 |

| Density | 3.85 g/cm3 |

| Specific Heat | 1.91 J/cm3 x K |

| Hygroscopic Susceptibility | Low |

| Thermal Expansion Coefficients | a, 4 x 10-6 /K; c, 36 x 10-6 /K |

| Thermal Conductivity | ⊥c, 1.2 W/m/K; //c, 1.6 W/m/K |

Linear Optical Properties:

| Transparency Range | 189-3500 nm |

| Optical Homogeneity | δn ~ 10-6/cm |

| Absorption Coefficient | < 0.1%/cm (at 1064 nm) |

| Sellmeier Equations (λ in µm) |

no2=2.7359+0.01878/(λ2-0.01822)-0.01354λ2 ne2=2.3753+0.01224/(λ2-0.01667)-0.01516λ2 |

|

Refractive Indices |

no = 1.6545, ne = 1.5392 no = 1.6606, ne = 1.5444 no = 1.6742, ne = 1.5547 no = 1.6930, ne = 1.5679 no = 1.7585, ne = 1.6126 |

| Thermo-optic Coefficients | dno/dT = -9.3 x 10-6/°C dne/dT = -16.6 x 10-6/°C |

Nonlinear Optical Properties:

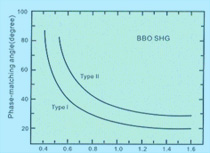

| Phase-matchable SH Wavelengths: | 189 - 1750 nm |

| NLO Coefficients (x//m) |

d11 = 5.8 x d36(KDP) = 2.26 pm/V d31 = -0.05 x d11 = -0.11 pm/V |

| Effective Nonlinearity Expressions | dooe = d11 cos3φ * cosθ - d31 sinθ deoe = d11 sin3φ * cos2θ |

| Electro-optic Coefficients | γ11 = 2.7 pm/V, γ13, γ33 < 0.1 γ11 |

| Half-wave Voltage | 48 kV (at 1064 nm) |

| Damage Threshold (Bulk) at 1064 nm at 532 nm |

5 GW/cm2 (10 ns); 10 GW/cm2 (1.3 ns) 1 GW/cm2 (10 ns); 7 GW/cm2 (250 ps) |

Application Examples:

BBO is of particular importance in the visible and far UV. A wide variety of phase-matching applications are possible, including the following:

SHG and SFG

BBO is the only NLO material which can be used to produce the fifth harmonic generation (5HG) of Nd:YAG lasers at 213 nm. Because of a small acceptance angle and large angular walkoff, good laser beam quality (small divergence, good mode condition, etc.) is the key for BBO to obtain high conversion efficiency. Tight focus of laser beam is not recommended.

| NLO properties for harmonic generations with Type I PM in BBO crystal | ||||

| Harmonics | SHG | THG | 4HG | 5HG |

| Effective NLO Coefficient( x d36(KDP) ) | 5.3 | 4.9 | 3.8 | 3.4 |

| Acceptance Angle (mrad-cm) | 1.0 | 0.5 | 0.3 | 0.2 |

| Walk-off Angle (°) | 3.2 | 4.1 | 4.9 | 5.5 |

OPO and OPA

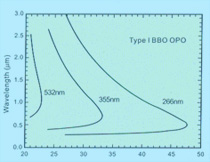

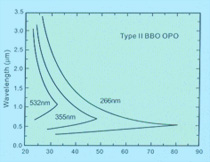

The OPO and OPA of BBO are powerful tools for generating a widely tunable coherent radiation from the UV to IR. The tuning angles of type I and type II BBO OPO and OPA have been calculated, with the results shown in following, respectively.

|

|

|

| Type I OPO Tuning Curves | Type II OPO Tuning Curves |

Ultrafast Laser (Ti:sapphire)

Frequency doubling and tripling of ultrashort lasers are the applications in which BBO shows superior properties to KDP or ADP crystal. BBO crystals as thin as 0.01 mm (10 µm ) for these purposes are available. A laser pulse as short as 10 fs can be efficiently frequency doubled with an ultrathin BBO crystal with the minimal group-velocity matching.

Specifications of BBO components:

| Wavefront Distortion: | < λ/8 @ 633 nm for Aperture =< 5mm, L =< 5mm |

| Dimension Tolerance: | (W+/-0.1 mm) x (H+/-0.1 mm) x (L+0.2/-0.1 mm) |

| Clear Aperture: | > 90% central area |

| Flatness: | λ/8 @ 633 nm |

| Surface Quality: | Scratch/Dig 10/5 per MIL-O-13830A |

| Parallelism: | better than 20 arc seconds |

| Perpendicularity: | 5 arc minutes |

| Angle Tolerance: | Δθ < 0.25o, Δφ < 0.25o |

Coatings:

1. Protective coating (P-coating): This is a single-layer MgF2 coating protecting a polished surface of BBO crystal from fogging due to ambient moisture. It also partially reduces reflection from the polished surface at a certain wavelength range.

Coating curve: P-coating (typical).

2. Anti-reflective coatings (AR coatings): These are multi-layer dielectric coatings. Single-band, dual-band or broad-band AR coatings on BBO surfaces are available upon request.

Coating curves: AR532/266 nm, AR1064/532 nm, AR800/400 nm, AR710/355 nm (typical).

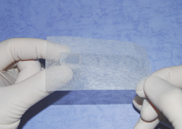

Mounts:

For customer convenience the crystals can be mounted in an 1" anodized aluminum (Al) mount. The mounted crystals can be further mounted in a conventional 1" mirror mount to be angle tuned for phase matching (as shown to the right). Water-cooled mounts for high power applications can be offered upon request.

BBO Crystal Handling:

BBO has a low susceptibility to moisture. The AR coating or the protective coating (P-coating) on the crystal faces can protect the faces from moisture to some extent. It is fine to leave the crystal in the setup for most optics labs with RH =< 40%. However, we recommend storing the crystal in a desiccator if it will be unused for over > 2 weeks. This will help maximize the crystal's lifetime. Alternatively, a small enclosure (with openings for light) may be built around the crystal with a continuous flow of dry nitrogen of air into the enclosure. The dry nitrogen/air pressure needs only to be slightly above the atmosphere to keep the small volume around the crystal dry and clean.

BBO is relatively soft and therefore requires precautions to protect the surfaces.

Cleaning Crystals:

Dust and stains on crystal surfaces can cause scattering/loss of light and can even react with light to damage optical surfaces at a high incident laser power.

Inspect the crystal surface for dust and stains by holding it near a bright visible-light source. Viewing at different angles can help see scattering from dust and stains. The crystal surface has to be cleaned as described below if dust and stains are found.

Note: Perform the following cleaning procedures in a clean, low-dust environment while wearing powder-free gloves or finger cots.

1. Blowing off the crystal surface

Use a canister of compressed N2/clean air or a blower bulb (e.g., http://www.adorama.com/GTRABS.html ) to blow off dust and other loose contaminants first. If a dry nitrogen line is available in the lab, an air gun can also be used to blow away dust particles. Blow off the surface gently. Do not blow off the crystal itself from your hand!

2. Drop and Drag Method

Hold the crystal so that the c rystal surface is horizontal and slightly above your fingers. Take a fresh, clean sheet of lens tissue and place it on the crystal. Make sure the lens tissue can be drawn across the crystal surface. Next, place a small drop of pure isopropyl alcohol (IPA) on the lens tissue on top of the crystal surface. The weight of the solvent will cause the lens tissue to come into contact with the crystal surface. Slowly but steadily drag the damp lens tissue across the crystal surface being careful not to lift the lens tissue off of the surface. Continue dragging the lens tissue until it is off of the surface.

rystal surface is horizontal and slightly above your fingers. Take a fresh, clean sheet of lens tissue and place it on the crystal. Make sure the lens tissue can be drawn across the crystal surface. Next, place a small drop of pure isopropyl alcohol (IPA) on the lens tissue on top of the crystal surface. The weight of the solvent will cause the lens tissue to come into contact with the crystal surface. Slowly but steadily drag the damp lens tissue across the crystal surface being careful not to lift the lens tissue off of the surface. Continue dragging the lens tissue until it is off of the surface.

The amount of the solvent can be adjusted for various crystal size so the lens tissue is kept damp for the entire drag but there is not any visible trace of solvent on the crystal surface after the drag is finished. Inspect the surface and repeat if necessary, but only use each sheet of lens tissue once.

If the crystal surfaces are still “dirty” after the above cleaning procedures, the surfaces might have been damaged. Please contact us for rework of the crystals.

If you do not find the suitable products above, you may let us know your requirements or applications in the form below. Our sales or technical staff will get back to you as soon as possible.

Please provide your contact information for us to get back to you:

Name:Title:

Organization:

Work Phone:

E-Mail Address:

Enter the code in the box below: