Quartz Birefringent Filter Plates

The birefringent filter plate is a linear retarder made of a-cut (or 90o cut with the optical axis in the plate face) crystalline quartz and used intracavity to selectively tune a desired wavelength and create reflection losses at other wavelengths. In use, it is placed at Brewster’s angle, and then rotated about the axis perpendicular to the surface to achieve a full wave retardation at the wavelength of interest. The selected wavelength contains only a p-polarization component, and thus experience no reflection loss. Other wavelengths undergo a different retardation, and have some amount of s-polarization, leading to reflection losses.

A birefringent filter used in a short-pulse laser cavity can be a single quartz plate. A birefringent filter for a narrow linewidth CW laser can contain a stack of 2–4 quartz plates, each plate being half the thickness of the previous one. The thickest plate sets the bandwidth and the thinnest the free spectral range (FSR).

Reference:

![]() Birefringent filter for laser tuning: theory and design

Birefringent filter for laser tuning: theory and design

The birefringent filter plates in this page have a thickness of multiples of T (T=0.5mm) with the diameter of 1" or 0.5". More quartz plates/blocks with various apertures, thicknesses and coatings are available under the general "Quartz Crystals".

| Part No. | Description | Aperture | Thickness | Price | Availability | Add to Cart |

Basic Properties of Quartz Crystal:

| Transparency Range: 200 - 2300 nm |

|

|||

| Crystal Symmetry: Hexagonal, P3121 | ||||

| Lattice Constants: a=b=4.9133A, c=5.4053A | ||||

| Density: 2.65 g/cm3 | ||||

| Thermo-Optic Coefficients: dno/dT= -0.52 x 10-6 /oC @ 530 nm dne/dT= -0.63 x 10-6/oC @ 530 nm |

||||

| Damage Threshold ( 10ns, 10Hz) ~ 1GW/cm2 at 1064 nm ~ 500 MW/cm2 at 532 nm |

||||

| Optical Homogeneity: Δn < 10-6/cm | ||||

| Mohs Hardness: 7 | ||||

| Thermal Expansion Coefficients: | αa = 14 x 10-6/K αc = 7.6 x 10-6/K |

|||

| Linear Absorption Coefficients: α<0.01cm-1 from 300 to 2300 nm | ||||

|

Sellmeier Equations: (λ in µm) : |

||||

| Wavelength(nm) | no | ne | Birefringence (Δn=ne-no) |

Walk-off Angle at 45° |

| 1064 | 1.5341 | 1.5428 | 0.00872 | -0.325° |

| 800 | 1.5384 | 1.5473 | 0.00891 | -0.331° |

| 632.8 | 1.5427 | 1.5517 | 0.00906 | -0.336° |

| 532 | 1.5469 | 1.5561 | 0.00920 | -0.340° |

| 400 | 1.5577 | 1.5673 | 0.00957 | -0.351° |

| 355 | 1.5646 | 1.5744 | 0.00982 | -0.358° |

| 266 | 1.5916 | 1.6024 | 0.01077 | -0.386° |

Specifications:

| Cut Orientation: | a-cut +/-5 arc min with the optical axis (c-axis) in the plane surface |

| Diameter Tolerance: | +0, -0.25 mm |

| Thickness Tolerance: | +/-0.05 mm for T=<5mm, +/-0.1 mm for T>5mm |

| Surface Quality: | 10/5 Scratch and Dig |

| Parallelism: | < 3 arc sec |

| Perpendicularity: | <10 arc min |

| Transmission Wavefront Distortion: | <λ/8 @632.8 nm |

|

AR-coating: |

R<0.2% at the central wavelength is available upon request |

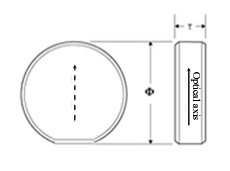

Cut orientation (a-cut):

If you do not find the suitable products above, you may let us know your requirements or applications in the form below. Our sales or technical staff will get back to you as soon as possible.

Please provide your contact information for us to get back to you:

Name:Title:

Organization:

Work Phone:

E-Mail Address:

Enter the code in the box below: