LBO Crystals

LBO crystal is one of the most versatile nonlinear optical crystal materials available. It has a very broad transmission range from vacuum UV to mid infrared, a very high damage threshold (actually the highest among the common nonlinear crystals) and is capable of noncritical phase matching (NCPM) in the near IR region, making it the material of choice for high power, high efficiency second harmonic generation (SHG) and optical parametric processes (OPO/OPA). Newlight Photonics keeps a large stock of LBO crystals which can be delivered within one week upon receipt of the purchase order. (*Availability is subject to change)

LBO products on this page are thick crystals (>= 3 mm) for applications with picosecond (ps), nanosecond (ns), or long pulse/CW lasers.

For thin LBO products (Thickness < 3mm) developed for frequency conversions of ultrafast femtosecond (fs) lasers, please go to thin LBO crystals.

Crystals for NCPM at an elavated temperature can be premounted in an oven with precision controller. Crystals used at ~ 20 - 50 oC can also be premounted in a compatible water-cooled or TEC (ThermoElectric Cooler) cooled mount upon request.

| Part No. | Description | Application | Size | Price | Availability | Add to Cart |

Newlight's LBO features:

| |

| |

| |

| |

| |

| |

| |

Structural and Physical Properties:

| Crystal Structure | Orthorhombic, Space group Pna21, Point group mm2 |

| Cell Parameters | a=8.4473 Å, b=7.3788 Å, c=5.1395 Å, Z=2 |

| Melting Point | ~834 °C |

| Mohs Hardness | 6 |

| Density | 2.47 g/cm3 |

| Hygroscopic Susceptibility | Low |

| Thermal Expansion Coefficients | αx=10.8x10-5/K,αy= -8.8x10-5/K,αz=3.4x10-5/K |

| Thermal Conductivity | 3.5 W/M/K |

Linear Optical Properties:

| Transparency Range | 160 - 2600 nm |

| Thermo-optic Coefficient (1/°C, λ in µm) |

dnx/dT = (-3.76λ+2.30) x 10-6 dny/dT = (6.01λ-19.40) x 10-6 dnz/dT = (1.50λ-9.70) x 10-6 |

| Optical Homogeneity | δn ~10-6 /cm |

| Bulk Absorption Coefficient | < 100 ppm/cm at 1064 nm, < 150 ppm/cm at 532 nm |

| Sellmeier Equations (λ in µm) |

nx2=2.454140+0.011249/(λ2-0.011350)-0.014591λ2-6.60x10-5λ4 ny2=2.539070+0.012711/(λ2-0.012523)-0.018540λ2+2.00x10-4λ4 nz2=2.586179+0.013099/(λ2-0.011893)-0.017968λ2-2.26x10-4λ4 |

| Refractive Indices: @ 1064 nm @ 532 nm @ 266 nm |

nx = 1.5656, ny = 1.5905, nz=1.6055 nx = 1.5785, ny = 1.6065, nz=1.6212 nx = 1.5973, ny = 1.6286, nz=1.6444 |

Nonlinear Optical Properties:

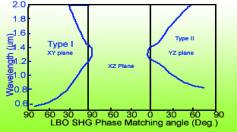

| SHG Phase Matchable Range | 551 ~ 2600 nm (Type I); 790-2150 nm (Type II) |

| NLO Coefficients | d31=1.05 ± 0.09 pm/V d32= -0.98 ± 0.09 pm/V d33=0.05 ± 0.006 pm/V |

| Effective Nonlinearity Coefficients | dooe=d32cosφ(in XY plane) deeo=d31cos2θ+d32sin2θ (in XZ plane) doeo=d31cosθ(in YZ plane) deoe=d31cos2θ+d32sin2θ (in XZ plane) |

| Damage Threshold (Bulk) @ 1064 nm @ 532 nm |

9 GW/cm2 (9 ns); 19 GW/cm2 (1.3 ns) 2.2 GW/cm2 (10 ns); 45 GW/cm2 (100 ps) |

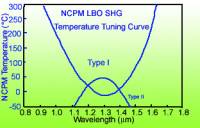

| NCPM Temperature | 148 oC for SHG @ 1064 nm, 162 oC for SHG @ 1053 nm 172 oC for SHG @ 1047 nm |

Damage Threshold:

LBO has a very large bulk damage threshold and is the crystal of choice for high power second and third harmonic generations of Nd:YAG, Nd:YLF, and Nd:YVO4 lasers,

Comparison of bulk damage threshold (@1064 nm, 1.3 ns):

| Crystal | Energy Fluence (J/cm2) | Power Density (GW/cm2) |

| KTP | 6.0 | 4.6 |

| KDP | 10.9 | 8.4 |

| BBO | 12.9 | 9.9 |

| LBO | 24.6 | 18.9 |

Application Examples:

| SHG-554 nm, THG-794 nm, SFM-down to 160 nm |

| |

| |

| |

| |

| |

| |

| |

SHG and THG at Room Temperature:

LBO is phase matchable for the SHG and THG of Nd:YAG and Nd:YLF lasers, using either type I or type II interaction. For the SHG at room temperature, type I phase matching can be reached and has the maximum effective SHG coefficient in the principal XY and XZ planes in a wide wavelength range from 551 nm to about 3000 nm. LBO is the first choice for making doubler or tripler for lasers such as Nd:YAG where high power density, high stability, and long time operation are required.

|

|

|

|

SHG tuning curves of LBO |

NCPM temperature tuning curves of LBO |

|

|

Non-Critical Phase-Matching at an Elevated Temperature:

|

|

|

|

|

|

LBO can reach both temperature NCPM and spectral NCPM (with a very wide spectral bandwidth) at 1300 nm. This is favorable for the SHG of very broadband or ultrafast pulses at ~ 1300 nm.

Properties for type I NCPM SHG at 1064 nm:

| NCPM Temperature | 14 8°C |

| Acceptance Angle | 52 mrad-cm1/2 |

| Walk-off Angle | 0 |

| Temperature Bandwidth | 4 °C-cm |

| Effective SHG Coefficient | 2.69 x d36(KDP) |

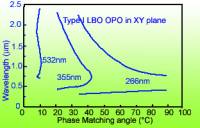

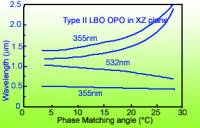

OPO and OPA with LBO:

LBO is an excellent NLO crystal for OPOs and OPAs with a widely tunable wavelength range and high powers. The unique properties of type I and type II phase matching as well as the NCPM leave a big room in the research and applications of LBO's OPO and OPA.

|

|

|

| |

| |

| |

| |

| |

LBO Specifications:

| Wavefront Distortion | < λ/8 @ 633 nm for Aperture =< 5mm, L =< 5mm |

| Dimension Tolerance | (W+/-0.1 mm) x (H+/-0.1 mm) x (L+0.2/-0.1 mm) * (L+0.5/-0.1 mm) for large crystals. |

| Clear Aperture | > 90% central area |

| Flatness | λ/8 @ 633 nm |

| Surface Quality | Scratch/Dig 10/5 per MIL-O-13830A |

| Parallelism | better than 20 arc seconds |

| Perpendicularity | 5 arc minutes |

| Angle Tolerance | Δθ < +/-0.25o, Δφ < +/-0.25o |

Coatings:

The following coatings on LBO surfaces are available upon request:

(1) Multi-layer dielectric single-band, dual-band or broad-band AR coatings

Coating curves (typical):

AR1064/532 nm, AR1064/532/355 nm, AR976/473 nm, AR1550/775 nm,

Broad band AR for OPO/A

(2) Single-layer protective coatings (P-coating)

Coating curves: P-coating @ 400 nm

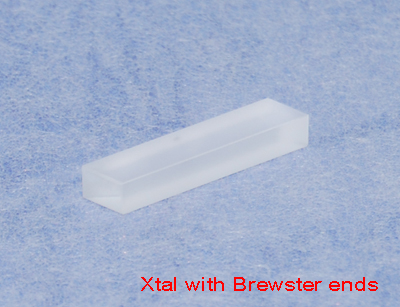

Brewster ends:

Brewster ends:

LBO crystals with one end or both ends cut at the Brewster angle and uncoated are available. Such crystals are often used to minimize the surface loss without reduction of the damage threshold by an AR coating for high power applications.

Mounts:

For customer convenience and protection of crystals, standard 1" anodized aluminum (Al) mounts can be offered upon request. The mounted crystals can be further mounted in a conventional 1" mirror mount to be angle tuned for phase matching (as shown to the right). For laser powers > 1 W, the standard aluminum mounts may not be suitable due to temperature increase of the crystal and the consequent output instability. Water-cooled mounts for high power application are available upon request.

Oven and temperature controller:

We provide precision oven and temperature controller to maintain LBO crystals at a preset temperature for noncritical phasematching (NCPM) for SHG and OPO/OPA. Crystals may be pre-installed into the oven free of charge in our factory for your convenience.

Learn more about oven and controller

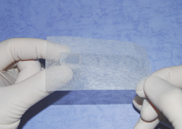

Cleaning Crystals:

Dust and stains on crystal surfaces can cause scattering/loss of light and can even react with light to damage optical surfaces at a high incident laser power.

Inspect the crystal surface for dust and stains by holding it near a bright visible-light source. Viewing at different angles can help see scattering from dust and stains. The crystal surface has to be cleaned as described below if dust and stains are found.

Note: Perform the following cleaning procedures in a clean, low-dust environment while wearing powder-free gloves or finger cots.

1. Blowing off the crystal surface

Use a canister of compressed N2/clean air or a blower bulb (e.g., http://www.adorama.com/GTRABS.html ) to blow off dust and other loose contaminants first. If a dry nitrogen line is available in the lab, an air gun can also be used to blow away dust particles. Blow off the surface gently. Do not blow off the crystal itself from your hand!

2. Drop and Drag Method

Hold the crystal so that the c rystal surface is horizontal and slightly above your fingers. Take a fresh, clean sheet of lens tissue and place it on the crystal. Make sure the lens tissue can be drawn across the crystal surface. Next, place a small drop of pure isopropyl alcohol (IPA) on the lens tissue on top of the crystal surface. The weight of the solvent will cause the lens tissue to come into contact with the crystal surface. Slowly but steadily drag the damp lens tissue across the crystal surface being careful not to lift the lens tissue off of the surface. Continue dragging the lens tissue until it is off of the surface.

rystal surface is horizontal and slightly above your fingers. Take a fresh, clean sheet of lens tissue and place it on the crystal. Make sure the lens tissue can be drawn across the crystal surface. Next, place a small drop of pure isopropyl alcohol (IPA) on the lens tissue on top of the crystal surface. The weight of the solvent will cause the lens tissue to come into contact with the crystal surface. Slowly but steadily drag the damp lens tissue across the crystal surface being careful not to lift the lens tissue off of the surface. Continue dragging the lens tissue until it is off of the surface.

The amount of the solvent can be adjusted for various crystal size so the lens tissue is kept damp for the entire drag but there is not any visible trace of solvent on the crystal surface after the drag is finished. Inspect the surface and repeat if necessary, but only use each sheet of lens tissue once.

If the crystal surfaces are still “dirty” after the above cleaning procedures, the surfaces might have been damaged. Please contact us for rework of the crystals.

If you do not find the suitable products above, you may let us know your requirements or applications in the form below. Our sales or technical staff will get back to you as soon as possible.

Please provide your contact information for us to get back to you:

Name:Title:

Organization:

Work Phone:

E-Mail Address:

Enter the code in the box below: